Flat roofs are standard features in Los Angeles buildings, thanks to their advantages in construction and maintenance. Therefore, flat roof installation has become a common service, depending on the client's preferences and type of building. While a flat roof design appears simple, the installation process involves meticulous processes that require precision for the best results. An improper installation process could cause significant losses in maintenance expenses, leading to frustrations.

Therefore, it is important to partner with a certified and experienced roof installation service provider who understands the craft. With our help, you can be confident that the installed flat roof will be durable enough to last for the recommended period. At Los Angeles Roof Experts, you get to partner with some of the best roof installation personnel for clients seeking services in Los Angeles, California. Our wealth of experience equips us with the necessary tools to ensure every installation is completed successfully.

Reasons For Flat Roof Preference in Los Angeles

With the growing preference for flat roof installation, you may be curious about the advantages that a flat roof offers. Some common benefits of a flat roof are:

It Creates a Desirable Modern Aesthetic

With the developments in architecture and general interest in futuristic styles, most clients prefer flat roofs. They provide a unique aesthetic for residential homes, making the entire house stand out. Moreover, a flat roof allows the homeowner to use the roof space for gardening or relaxation.

A Flat Roof is Easy to Maintain

Similarly, the ease of maintenance makes a flat roof the better choice for many. Despite this, it is advisable to protect the roof from extreme damage, especially in extreme weather conditions. For example, you can occasionally check on the water drainage system to ensure that rainwater is draining correctly. The occasional checks reduce the degeneration period significantly.

Commercial Buildings Benefit from Additional Storage Space

Moreover, commercial building owners can benefit from the extra space that a flat roof creates. The space is often useful in holding air conditioning units that supply different floors in the building complex. This way, the building operators do not have to worry about mounting air conditioning units on the building sides requiring additional support.

The Flat Roof Offers a Basis for Expansion

Sometimes, you may decide to expand your home by building an extra floor. Since the roof does not have any metal sheets and ridges to tear down, your architect will build up from the roof and design an expansion with minimum deconstruction.

Flat Roofs are More Affordable as They Reduce the Building Volume

If you are constructing a home from the ground up, you may understand the expenses that come with it. Hence, if you are looking to cut costs with the assurance of a quality roofing, a flat roof is a great option.

Generally, the reduced building volume will also reduce the required construction material and labor. As a result, your building project may also take less time, helping you achieve your goals faster.

Flat Roof Material Types

When choosing the type of material to use in installing your flat roof, you will have several options to consider. Each flat roof material provides unique features that give them an advantage over the rest.

Moreover, costs may range between the different materials, leading to significant budget gaps. Therefore, you will need to consider the materials you need to include in your flat roof for compatibility in construction and finishing. Available flat roof materials include:

1. Polyvinyl Chloride Roofing

Thanks to their numerous advantages, polyvinyl Chloride (PVC) membranes are among the most common materials used for flat roof installation. Most people who prefer PVC flat roofs choose them for their low maintenance while providing a high life span of about fifteen to thirty years.

Additionally, you will have confidence in a PVC's durability, thanks to the reliable installation processes that fasten the membrane firmly. You will also have a sustainable flat roof with minimal leakage and risk of wind damage if installed correctly.

PVC Flat Roof Installation

During the installation of a PVC flat roof, we use the overlap method to install the membranes and secure the roof structure. The main component involved in the polyvinyl chloride membrane should measure at least three feet long. Since we install the membranes in an overlap system, there must be an overlap distance of six to eight inches long for proper reinforcement.

However, before reinforcing the overlapped membranes, we also place insulation boards to help create a conducive surface for efficient energy levels. Since the roof is exposed to alternating temperatures, the insulation board also helps manage irregular expansion and contraction that may cause quicker wear and tear.

When put in place, you may choose to have the PVC membranes reinforced using mechanical tools. The method is advisable, as the mechanical fixture using screws and nuts will reduce the hazards of wind uplifting the membrane.

On the other hand, adhesive reinforcement using hot air welding tools is also useful, although it does not guarantee reliable results compared to mechanical support. Nevertheless, it is suitable for the function and still provides a durable flat roof.

The hot air welding is ideal for the creation of roof seams that bind the membranes. It is important to note that the seams should ideally be stronger than the membrane to prevent possible uplift during strong winds.

Additionally, the flat roof is made three feet wide to reduce the risk of uplift removal during extreme weather conditions. We will fasten the roof membrane to your building's roof deck mechanically, on top of including seams and hot air welding as reinforcement.

2. Modified Bitumen Flat Roofs

Bitumen-Asphalt roof materials are also suitable alternatives for flat roofs, as they comprise several plies of roofing material. The different ply system creates a sturdy flat roof that can last for ten to twenty years.

Installation Process

Nevertheless, installing a flat bitumen roof is a long procedure, as it involves the placement of numerous layers. On top of this, each layer must be reinforced by torching the surface to the ground for durability. Subsequently, you need the services of experienced flat roof installers, as they understand the different processes to follow to create a complete structure.

3. Ethylene Propylene Diene Terpolymer (EPDM)

Another common flat roof material is EPDM, made of synthetic rubber. The material is popular for its eco-friendly and affordable pricing compared to other materials.

Moreover, installation is relatively easy because it involves a single application and reinforcement of the membrane. An EPDM roof will also last for ten to fifteen years without causing any problems.

Installation Process

Unlike PVC installation, EPDM materials only require a wide membrane instead of seams. In this case, seams would be more prone to leaks and wind lifts, creating risks of complete roof destruction.

Thus, the first step involves installing an insulating layer to manage energy efficiency and regulate its transmission and performance. Secondly, we will measure about fifty to two hundred inches of EPDM membranes to fix on the roof deck. When placing the membrane, it is crucial to perform the task to avoid air bubbles.

4. Thermoplastic Polyolefin (TPO)

Alternatively, you may choose the TPO roof membrane that comprises a single layer of the roofing membrane. Despite its simple composition, TPO roof membranes are water and UV light resistant, creating a great performance.

On average, the roof can serve for seven to twenty years, depending on the installation process and external weather conditions.

Installation Process

Like in other roof membranes, installation begins with placing an insulation board to regulate energy efficiency. The boards will lie on the roof deck and be fastened mechanically or using adhesive. After that, we then place the TPO membrane and reinforce it using a hot air welder. The heat will bond the TPO components chemically for a sturdy seal on the roof.

Causes of Flat Roof Deterioration

Like other roofs, a flat roof is prone to deterioration over time based on different circumstances. It is necessary to learn of the causative agents to manage them and prevent the avoidable factors. Common wear and tear that warrants roof repair include:

The Buckling of Roof Membranes

A flat roof installation places the entire roof surface in alignment with the building structure.Consequently, the expansion and contraction in the building during hot or cold weather causes a direct impact on the roof.

Depending on the type of membrane installed, your roof structure may begin to buckle up after ranging temperatures. As a result, the roof structure becomes more prone to leaks and cracks, especially in Asphalt roofs. Therefore, it is necessary to have repairs as soon as you notice membrane buckling.

Roof Cracks

Doubtless, cracks on your flat roof should be a cause of concern, as they indicate impending safety hazards. Cracks may emerge from different circumstances based on the type of roof membrane installed, the quality of the roof installation process, and external factors.

For example, if the person handling a PVC roof did not use enough adhesive for the membrane, it may crack eventually from the inadequate support. By the time cracks form on your flat roof, the underlying problem may have already got out of hand, requiring repairs expeditiously.

Water Leakages

Since rainfall is inevitable, your flat roof installation should include a water-resistant layer. However, some roofs are improperly designed, meaning that water will leak into the building.

Consequently, the building may continue to degenerate from fungi and mold that grows in the damp areas. In adverse cases, the dampness also leads to rots and increased porosity causing complete roof damage. You may have to replace the entire roof with a new one from the extreme water damage in these situations.

Alligatoring of the Roof Surface

Also, Asphalt roofs are prone to alligatoring, a condition where the roof surface wears out and forms bubbles. The name comes from the resemblance of the roof bubbles to an alligator's skin.

Upon the loss of elasticity, the flat roof can also begin to misalign during expansion and contraction, creating additional cracks. The dangerous state of the roof often warrants a complete replacement, as repairs may not get to the root of the problem.

Formation of Water Pools on the Roof

The flat roof design may cause persistent water pools after heavy downpours, especially when no proper fire boards and vent flashes are installed. The fire board is important in creating a gradient to help the water flow in one direction.

At the end of the slope, the roof should have a flash vent system to drain water away and prevent water pools. Hence, if your roof lacks these essential components, you may need to schedule a repair or replacement timeline. Working on the problems early enough will help you save on costs and future inconveniences.

Flat Roof Repairs and Replacements

Sometimes, the damage on your flat roof may not be significant enough to warrant a complete replacement. Subsequently, the appointed flat roof expert will only make changes to the affected areas.

However, prolonged damage leaves the flat roof in a poor state that often needs replacement. As discussed, the installation process and materials used to develop the flat roof play a significant role in dictating the procedures to follow.

Usually, Bitumen flat roof procedures provide comprehensive details in flat roof replacement, as they involve the most steps. Therefore, the following are replacements steps that may apply broadly for different flat roof types:

Remove the Damaged Roof Layers from the Roof Deck Completely

We begin the roof replacement process by removing the worn-out flat roof membranes to create space for new installations.

Since most membranes are fixed by adhesive or heat, the removal process may be tedious. Nevertheless, the worn-out conditions of materials will have made the adhesive loose to make it easier for removal.

The roof expert working with you will ensure that the procedure continues without mishaps, as improper removal may affect the roof deck or other parts of the building.

Install New Plywood

Afterward, we install new plywood to the roof base and firmly connect the house frame to the flat roof. Usually, plywood prevents moisture from reaching the roof dock and building walls.

The plywood performs this function by swelling when wet and drying up when dry. Since plywood material is useful in withstanding moisture for a long time, the other parts of the roof will be mistake-free to prevent decay.

Fix the Taper Edges and Fire Boards

As mentioned, water pooling is a common cause of flat roof degeneration. It occurs because of poor sloping that prevents water from draining properly. Therefore, it is important to install fire boards because they create a low pow ponding area. A slope arises from the structure, making water flow into the drains.

Taper edges are also essential to install in flat roof replacement, as they lock out moisture from the fire boards. In doing so, they will prevent conditions like warping and swelling from excessive moisture that could compromise the roof's condition.

Place the Basesheet on the Roof Deck

When the fire boards and taper edges are well fixed, we install the base sheet on the roof deck. Essentially, the base sheet provides a water-resistant top surface that protects the inner flat roof layers.

You should note that an ideal base sheet should be made of polyester or fiberglass for the best water-resistant features. Moreover, the materials work well during base sheet reinforcement, as we may have to use a torch down.

Install New Vents and Pipes to Drain Rainwater

The presence of vents and flash pipes on your flat roof is necessary for proper water drainage. Therefore, we will install new appliances at fixed points on the roof to maximize drainage.

Additionally, we are keen on priming the metallic pipe and vent surfaces. Priming prevents rusting and metal degeneration that may otherwise reduce the roof's lifespan.

Use a Flame Torch to Apply the Bitumen Surface

Lastly, we apply the final roof material at the top in preparation for work completion. The bitumen used in the final roof surfacing may also include non-solvent adhesives to seal membranes.

The Cost of Flat Roof Installation

In Los Angeles, flat roof replacement varies based on several factors. However, the average cost of roof installation ranges between $5 to $15 per square foot.

The most significant determining factor for costs in the flat roof material you chose to install and the building size. Each discussed building material offers different price ranges that include:

- Modified Bitumen roofs- $5.50 to $11.50 per square foot

- PVC flat roofs- $7 to $15 per square foot

- TPO roofs-$6.50 to $14 per square foot

- EPDM roofs-$6.50 to $12 per square foot

Find a Flat Roof Installation Professional Near Me

Installing a flat roof can be tedious and requires meticulous attention to avoid overlaps that could cost you in the future. With a professional’s help, you will receive services from a certified team that understands their craft and delivers high-quality results.

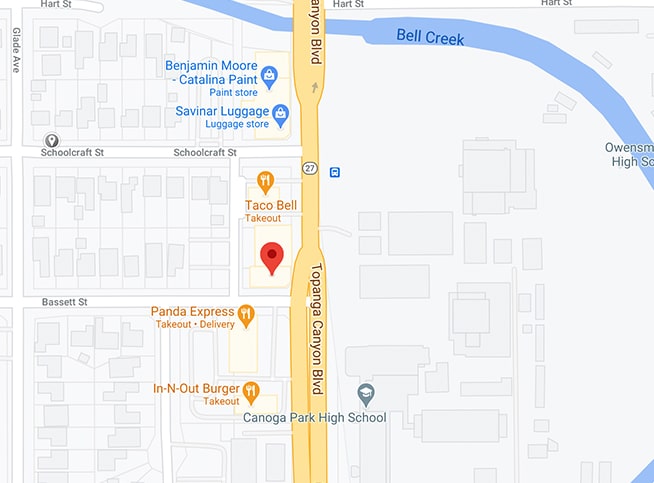

At Los Angeles Roof Experts, you can access roof installation services from some of the best professionals in Los Angeles, California. Our skills and work ethic aims at providing excellent results, regardless of the task at hand. To get in touch, give us a call today at 818-928-8374.